LowPro 23/05 Germany

We’ve put together a detailed case study guide – highlighting reputable legitimate clients in Germany who have not only seen huge benefits from using our LowPro 23/05 road plate, but have also provided excellent feedback.

Here at Oxford Plastics, we know how important it is to have full trust in your supplier. That’s why we’ve put together a detailed case study guide – highlighting reputable legitimate clients in Germany who have not only seen huge benefits from using our LowPro 23/05 road plate, but have also provided excellent feedback. So, if you’re thinking of purchasing these road plates for highways, streetworks, utilities sites or any construction work, these 3 case studies prepare you for what to expect from our product.

But firstly, it’s useful to understand exactly what the LowPro 23/05 is, and how it differs from other road plates.

What is the LowPro 23/05 road plate?

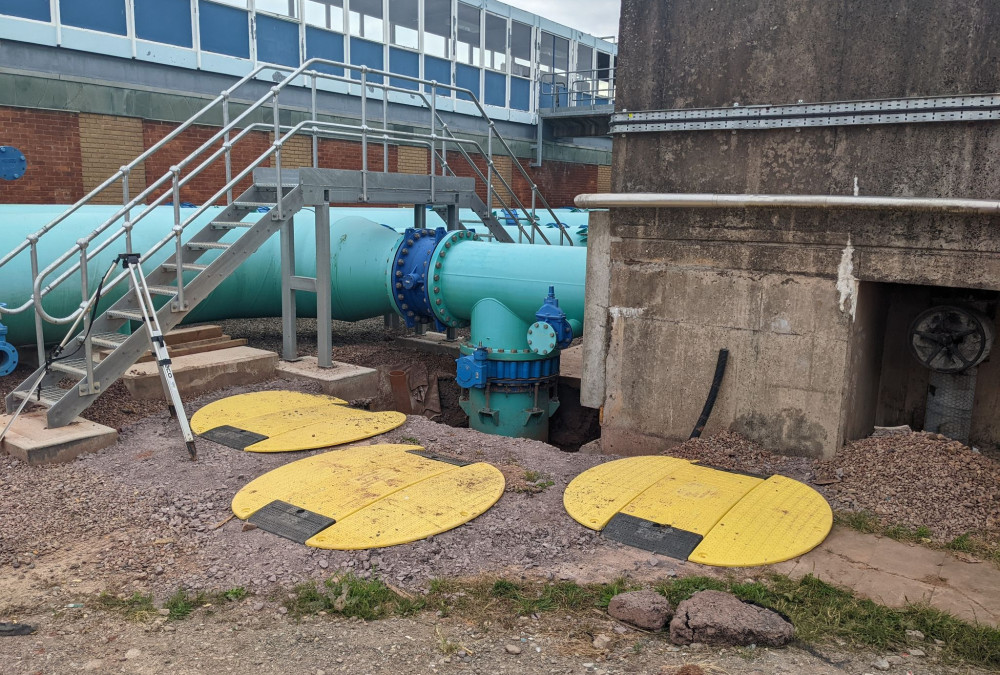

The LowPro® 23/05 is a modular system of singular linking units and is suitable for 44 tonnes vehicles over a 1200mm trench. With the capability of being installed manually, some of its many benefits include its anti-slide technology, hi-vis yellow colour scheme, and its ability to successfully reduce noise pollution.

Learn More

1. Markstahler Rohrleitungsbau GmbH

COMPOSITE ROAD PLATE AN EASY SOLUTION FOR GAS CONTRACTOR

Markstahler Rohrleitungsbau GmbH used the LowPro 23/05 Road Plate as a composite excavation cover in the installation of gas and water pipes in Germany.

Who they are:

- Markstahler Rohrleitungsbau GmbH are a Germany based company and are part of the gas supplying company Erdgas Schwaben and part of the Thüga AG group.

- They have a €4 million annual turnover with 50 employees.

- Their business safely cover utility cables and pipe excavations for routine works in streetworks and traffic management.

- They also install gas and water pipes, and energy and glass fibre cables.

What they wanted to achieve:

- To safely cover trenches for cable lines and gas and water pipes.

- To provide a better solution than the historically used steel plates.

- To allow rapid access to the excavation during works, where the excavation is temporarily filled up with gravel before re-instating the road surface.

- To negate the need for heavy-lifting equipment on work sites.

End result:

Markstahler Rohrleitungsbau have “only positive” feedback since adopting the LowPro® 23/05 Road Plate across the company in 2019. The road plate has been favoured for its “flexibility, being an easier way to build a temporary access over a trench, for providing higher traffic security and having a good external impact”.

The composite road plate, which is manually installed, means that there is no need for Markstahler Rohrleitungsbau to use lorries, excavators and cranes for transport. They find it an “easy solution to use during road works”.

2. Omexom AG

COMPOSITE ROAD PLATE IS A WINNER FOR CITY UTILITIES

Omexom AG used the LowPro 23/05 Road Plate as a composite excavation cover in the installation of gas and water pipes in Germany.

Who they are:

- Omexom AG is part of the Vinci Energies Group.

- Their work includes installing gas and water pipes, and energy and glass fibre cables.

- They have a €4 billion annual turnover, 23,000 employees and are based in Germany.

What they wanted to achieve:

- To safely cover trenches for gas and water pipes and glass fibre trenches.

- To provide a better solution than the historically used steel plates.

- To allow rapid access to the excavation during works, where the excavation is temporarily filled up with gravel before re-instating the road surface.

- To provide a manually handled solution to cover excavations quickly and safely.

End result:

Since 2019, Omexom AG have migrated from using traditional steel plates to the composite LowPro 23/05 Road Plate. The solution is a 2-man lift, making it easy to use and “saving time” over the course of the streetworks.

It has put Omexom in good stead with city utilities too; with “no complaints from local residents, because of noisy steel plates”, the solution has received “extremely positive feedback from employees and city utilities”.

The problem-solving road plate removes the “laborious work of laying steel plates with excavators/lifting equipment and increases working security of employees”.

3. Josef Schnell GmbH

COMPOSITE ROAD PLATE KEEPS CONSTRUCTION SITES NEAT & TIDY

Josef Schnell GmbH used the LowPro 23/05 Road Plate as a composite excavation cover in the installation of gas and water pipes in Germany.

Who they are:

- Josef Schnell is a family-owned construction company with 4 locations in the South West of Germany.

- They work with trenchless technologies in streetworks for installing gas and water pipes, and energy and glass fibre cables.

- They have a €20 million annual turnover.

What they wanted to achieve:

- To safely cover trenches for gas and water pipes and glass fibre trenches.

- To provide a better solution than the historically used steel plates.

- To allow rapid access to the excavation during works, where the excavation is temporarily filled up with gravel before re-instating the road surface.

- To provide a manually handled solution to cover excavations quickly and safely.

- To use on a variety of job lengths, from days to weeks.

End result:

Since 2018, Josef Schnell Gmbh have been using the composite LowPro 23/05 Road Plate alongside traditional steel plates. The company was drawn to the LowPro range from Oxford Plastics because it presented an “interesting innovation”.

With a wide variety of works, the company are pleased that they can use the LowPro Road Plates effectively on jobs spanning 2 days to many weeks.

Along with the benefits of being installed by hand, Josef Schnell have found that the hi-visibility product makes their “construction sites look very good”.

Ready to purchase your own LowPro 23/05 road plate? Get in touch with our expert team now. Alternatively, get to grips with what road plates are used for, steel road plates vs plastic road plates and the different types of road plates available – all from our ultimate guide to road plates article.

More Case Studies

Supply Chain Sustainability School

Circularity and sustainability are central to Oxford Plastic's identity as a family-run SME. Our customer, Speedy, approached...

Harris Water Mains Improve Public Safety

4th Generation New York water and sewer contractor Harris Water Mains prioritizes public safety by making the switch to compo...

Barhale Reduces Carbon Footprint with Oxford Plastics' Composite Road Plates

Learn how Barhale reduced their carbon footprint, improved efficiency and increased safety when trialling the LowPro range at...