Protecting History: LowPro 15/05 Road Plate at St Catherine's College

We all know that renovating a listed building is never straightforward, especially when that building is a modern architectural building like St Catherine’s College in Oxford. When Beard Construction was tasked with scaffolding the college for refurbishment, they faced a unique challenge: how to stabilise the scaffold structure without damaging the historic architecture or soft surrounding ground.

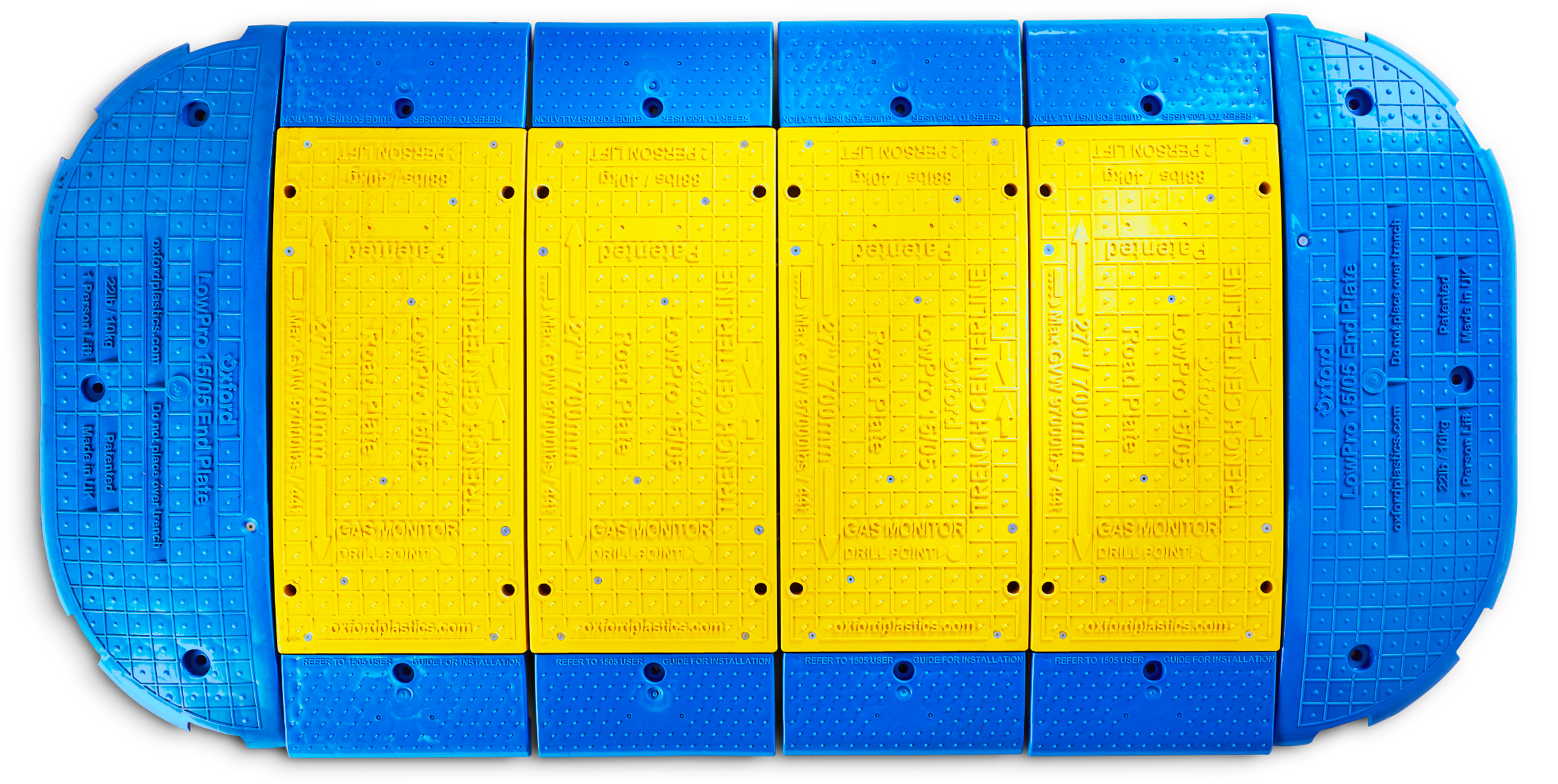

Thanks to a partnership between Beard Construction, distributor Hermeq, and Oxford Plastics, the solution came in the form of a smart, non-invasive scaffold load management system, the LowPro 15/05 Road Plate.

The Challenge: Working on a Grade I Listed Structure

Scaffold Support Without Structural Ties

As a Grade I listed building, St Catherine’s College could not have any conventional scaffold ties drilled into its structure. This meant that the entire scaffold frame had to be braced from the ground, which is not an easy task when working with soft terrain.

Additional challenges included:

- Unstable or uneven ground conditions

- The use of Monoflex sheeting, increasing wind load and structural strain

- Protecting delicate stonework and surfaces from heavy load impact

Conventional methods posed a serious risk of damage to the building’s foundations, flooring and aesthetics. So, each scaffold tube (standard) was estimated to exert up to 9 tonnes of force onto the ground.

The Solution: Oxford Plastics' LowPro 15/05 Road Plate

Superior Load-Spreading, Designed for Sensitive Environments

To overcome these challenges, 880 units of LowPro 15/05 Road Plates were deployed across the site in collaboration with scaffold subcontractor Lee Marley Brickwork and distributor Hermeq.

The LowPro 15/05:

- Distributed scaffold loads across a wider area

- Prevented pressure from concentrating in one location

- Required no ground excavation or mechanical fixings

- Offered high load-bearing capacity while being lightweight and easy to install

In critical zones, the LowPro 15/05 was used with railway sleepers to enhance load distribution even further.

“The LowPro 15/05 Road Plate was designed to address sensitive areas where reliable load-bearing is of utmost importance. We’re proud that our product enabled Beard Construction to maintain the integrity of a listed building while ensuring site safety and operational efficiency. Innovation for us means creating solutions where traditional methods fall short.”

– Charlotte Whiteley, Sales & Marketing Director, Oxford Plastics

Hermeq's Role: Smart Product Distribution & Specification

As a trusted distributor, Hermeq played a key role in sourcing and configuring the LowPro system to meet the project’s specific requirements.

Their involvement ensured:

- Rapid product delivery

- Proper load configuration across varied terrain

- Consistent communication between all stakeholders

“For this project at St Catherine’s College, we understood the sensitivity and complexity of working on a listed building. By supplying the LowPro 15/05 Road Plates, we were able to provide Beard Construction and Lee Marley Brickwork with a product that solved multiple challenges - ensuring scaffold stability, protecting historic surfaces, and doing so efficiently and cost-effectively.”

– Ben Buckley, Sales Director, Hermeq

Beard Construction: A Commitment to Craftsmanship and Care

Beard Construction is well-known for combining meticulous craftsmanship with practical, forward-thinking solutions. Their ability to manage scaffold engineering on such a protected site is testament to their commitment to:

- Heritage preservation

- Safe construction methods

- Collaboration with product innovators like Oxford Plastics

“The LowPro 15/05 Road Plates provided an ideal ground-based solution, enabling us to safely distribute the scaffold load without any impact on the building fabric. It was a critical component in allowing the works to proceed smoothly and compliantly.”

– Charlie Gostling, Assistant Site Manager, Beard Construction

Outcome: Safe, Non-Invasive Scaffold Support for a Historic Icon

The result was a freestanding scaffold system that protected both people and property:

- Zero impact on the listed structure

- Improved worker safety during high-wind conditions

- Preservation of delicate stone flooring

- Compliance with temporary works standards

The case highlights the versatility of the LowPro 15/05 not just as a trench cover, but as a high-performance load-spreading system in sensitive, high-risk environments.

Final Thoughts: Innovation That Preserves Our Past

Oxford Plastics’ commitment to solving real-world site safety challenges shines through in this case study. The collaboration between Oxford Plastics, Hermeq, and Beard Construction proves that with the right technology and partnerships, modern construction can respect and preserve our architectural heritage.

If you’re working on a sensitive or listed site, discover how the LowPro range can help you protect the past while building the future.

Related News

An Industry Guide to LowPro Road Plates and Trench Covers

Across construction and utilities in gas energy, waste-water, water suppy and fibreoptic works, keeping people safe and sites...

What are the risks of slips trips and falls on a works site

Working on a construction site, it can be challenging to reduce the risks of slips, trips and falls that arise due to wet and...

Deciding when to repair and when to recycle your safety products

Here at Oxford Plastics, we’re big on sustainability. Our products are designed with sustainability in mind and 75% of...